Monday, April 27, 2015

Framing and joints

at

1:48 PM

Sunday, April 12, 2015

more shapes

at

9:02 AM

Saturday, April 11, 2015

FRANTIC!

So this weekend is going to be a pain. I have to spend it in the studio, which is awesome but I have to finish at least five pieces (which is probably not going to happen) I am working on so many things at once that my brain is going to explode.

The best part is that I am very excited with the results of my enameling tests. Fingers crossed I leads to new and exciting things. I hope that these pieces will be going to SNAG this year for the Smitten show. I still have a lot of work to make for other things. Such as the Arrowmont instructor show, a collaboration piece for a show in NYC, a long over due trade, a faculty show, the jewelry exchange. The list goes on but I wont bore you with the details.

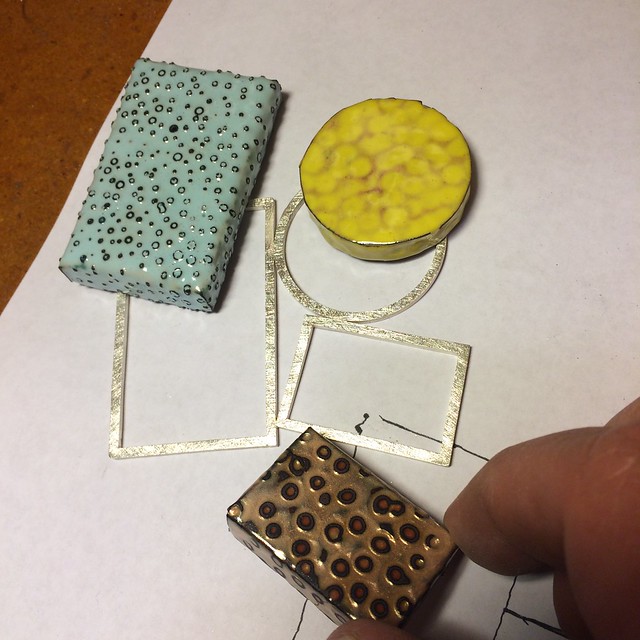

The components below will eventually become pieces. I am having a hard time deciding which of them go together. The more I make the more combinations/possibilities there are. Something inside of me wants to keep them all to be separate but I also think some of them look great together. I guess I will keep making them and see what happens.

On a separate note I bought a small toaster oven to try my hand at powder coating. After seeing a demo at the ECU symposium, it has been on the back burner and I would love to incorporate some of what I am doing here with powder coating. Maybe small TIG welded pieces?

Posted by

arthur hash

Labels:

arthur hash,

ArthurHash,

ECU symposium,

enamel,

New work,

Smitten Forum

0

comments

at

6:20 AM

Thursday, April 9, 2015

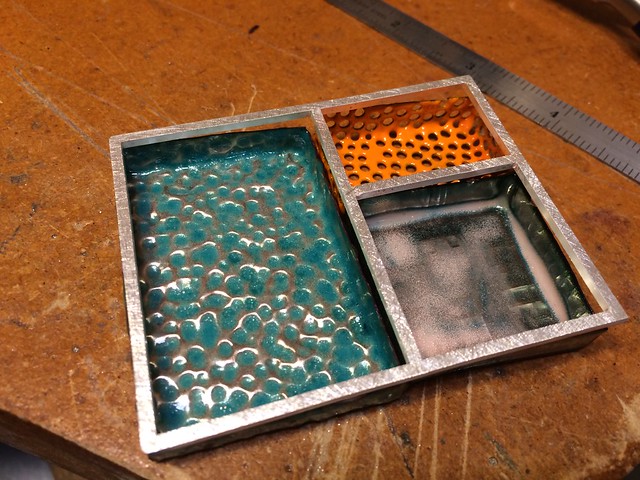

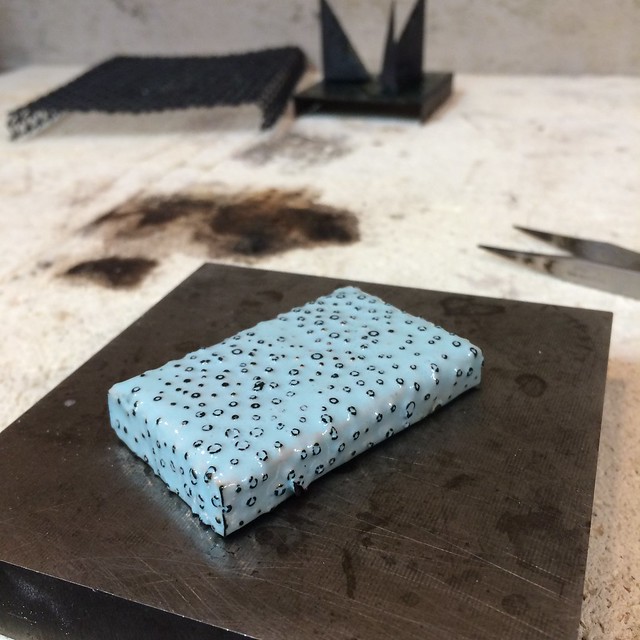

I have been making some moves with my enamel work lately. These pieces are just experiments but I am open to actually using them in a piece or two. I am frantically putting together work for a million things. These pieces will be exhibited at SNAG for the Smitten Forum 2 Exhibition.

I took this opportunity to do a little step by step thing for my enameling class this semester. The video at the end that shows the little flecks of copper that have been revealed from the diamond file. I am digging the format. I am going to have to do some stress tests to make sure it doesn't crack and of course I have to fabricate all the frames. So far the best part is making them!

I took this opportunity to do a little step by step thing for my enameling class this semester. The video at the end that shows the little flecks of copper that have been revealed from the diamond file. I am digging the format. I am going to have to do some stress tests to make sure it doesn't crack and of course I have to fabricate all the frames. So far the best part is making them!

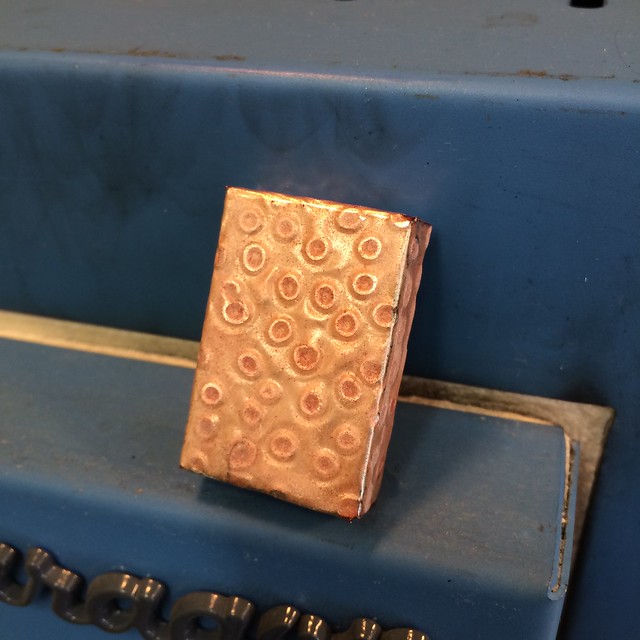

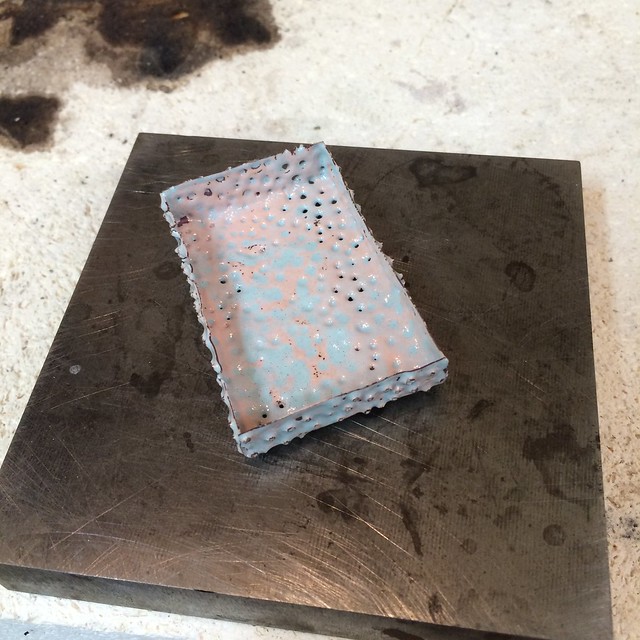

Step one: I started with 30 gauge copper. I used a center punch to pierce the surface. A lot.

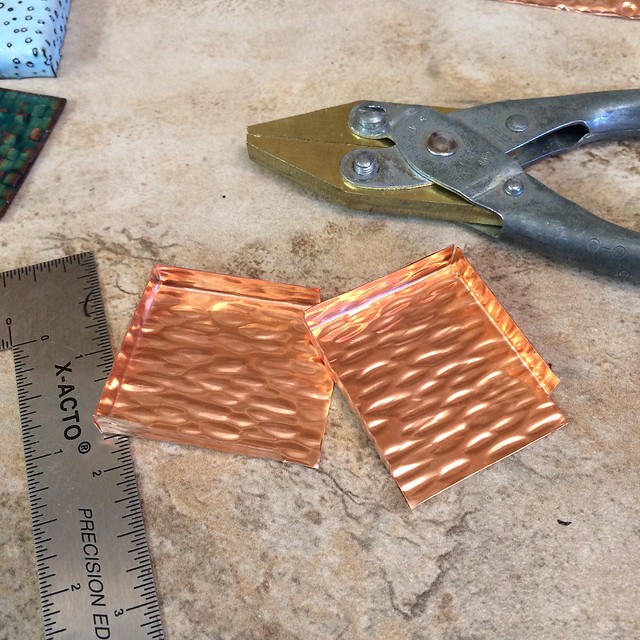

Step Two: Using plate shears I cut out a box form and folded it up with my brass jawed pliers.

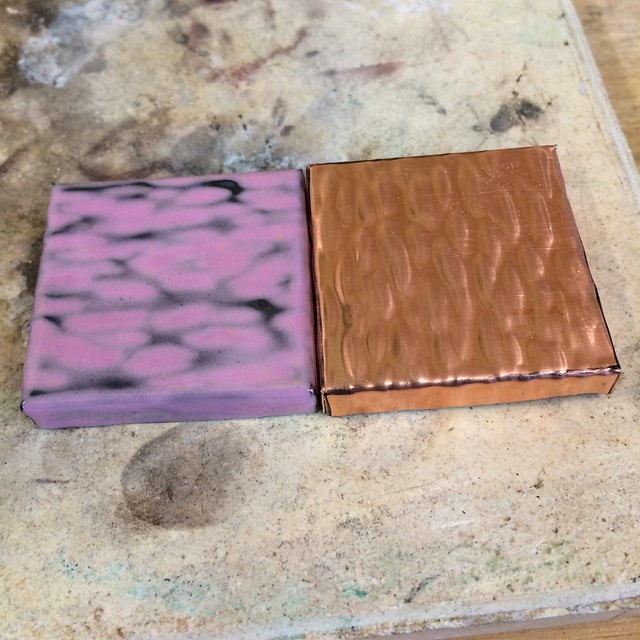

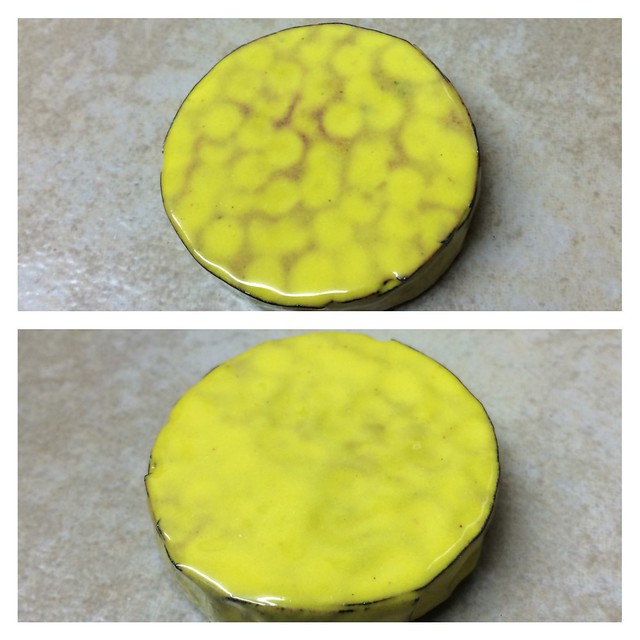

Step Three: Using A-4 I painted the entire piece. Make sure you get every nook and cranny.

Step Four: I basically dumped enamel all over the piece and shook off the excess. I fired the piece to 1475 F. It was a super thin coat. I didn't want it to burn before I could get the next coat on. I repeated the paint and coating and firing. Be careful to to burn your thin enamel shell!

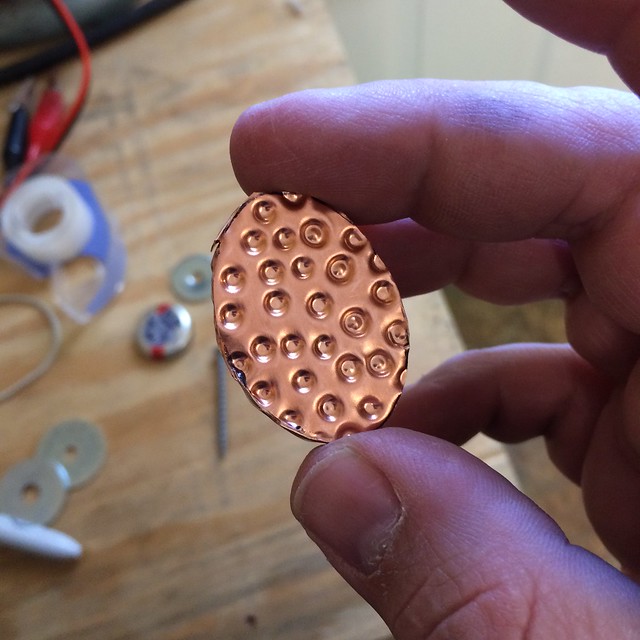

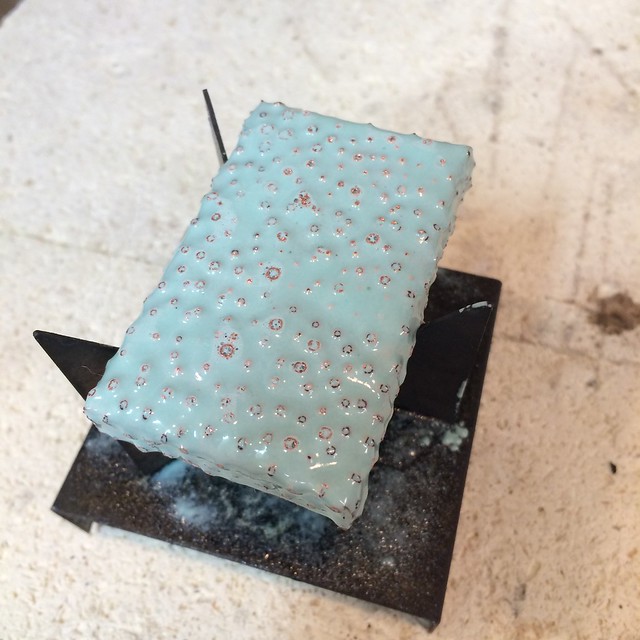

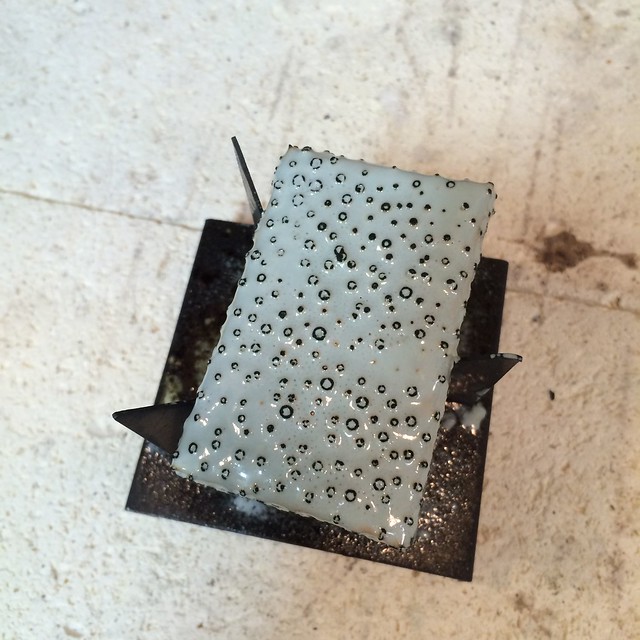

Step Five: Once I had a decent coating on the surface (no copper showing. Almost a solid color) I used my diamond file and filed down the surface. This revealed small circles left by the punch. After I filed down the surface sufficiently I dried off the piece on the door to the kiln.

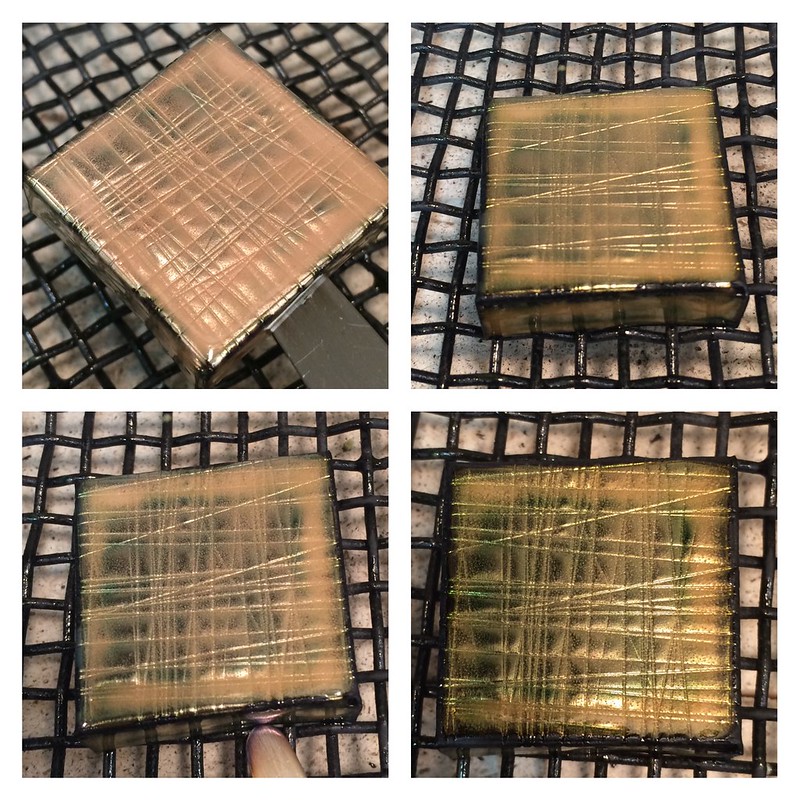

Step Six: Once dry, I re-fired it. I actually over fired it. I brought it up to 1524-ish for about three minutes. This over-fired the enamel and wherever the copper was revealed it left a really nice black edge.

I tried this a couple of different ways. I used a dapping punch to make the white block (featured in the video) and a whitney punch (Which I will demo in class) for the orange block.

Posted by

arthur hash

Labels:

arthur hash,

ArthurHash,

enamel,

jewelry,

New work,

Smitten Forum

0

comments

at

3:54 AM

Subscribe to:

Posts (Atom)

.jpg)