Thursday, April 28, 2016

Junior CAD/CAM class

Here are a few images of the necklaces made by my students in the CAD/CAM II class here at RISD. I am very excited what doors these pieces will open for the students. So many options for them now. Its a whole new world. Go team!

at

2:16 PM

Wednesday, April 27, 2016

Saturday, April 23, 2016

quick visit to lee allen eyewear

I received an email from a friend at ASU about an eyewear company near providence that was interested in a collaboration/buying equipment/renting space. When I arrived I was thrilled to see a mini manufacturing plant in an old mill building. It had everything all in the space of a few studio spaces.They are designing, prototyping and manufacturing limited runs. I was thrilled to see a ton of CNC machines, pneumatic punches, ultrasonic welders, mass tumblers. It turns out that one of them graduated from the Appstate metals program! Go Neers!

Decland and Lee were kind enough to give us a tour. We basically just went around to each machine making a pair of glasses. Machine by machine we cut, milled, routed, CNC'd, welded, injected and branded a complete pair of glasses. It was a great experience and I hope we can figure out something to do with them in the future.

I was sooooo excited I forgot to take more photos!

Thanks for the tour.

at

5:12 AM

Friday, April 15, 2016

Tuesday, April 12, 2016

a few things

With midterms over it has been a whirlwind of activity. I have not yet had the time to decompress but everything has to keep moving forward. I am demoing sculptris in my CAD/CAM II class. This will be our soft intro to 3D scanning and Zbrush. I am thrilled to get to teach what I actually want to teach with the tools I need to teach them. The sophomores did a vinyl cut wearable using illustrator and the vinyl cutter! They kind of knocked it out of the park.

On another note I threw a ASIGA print under the microscope. The layering is nuts. This was at .5mm Z layer (the lowest/coarsest resolution). The ASIGAs will print at .01mm which is incredibly fine but of coarse takes forever. I have been printing all of my students stuff so there has been almost no down time with the printers.

I GOT A MICROSCOPE. The nature lab at RISD hooked me up with an older microscope that they were decommissioning. I bought an articulating arm on amazon and boom now I have a microscope at the bench. I have put most of my stone setting on pause to to focus on other things but I promise I will do thorough review later.

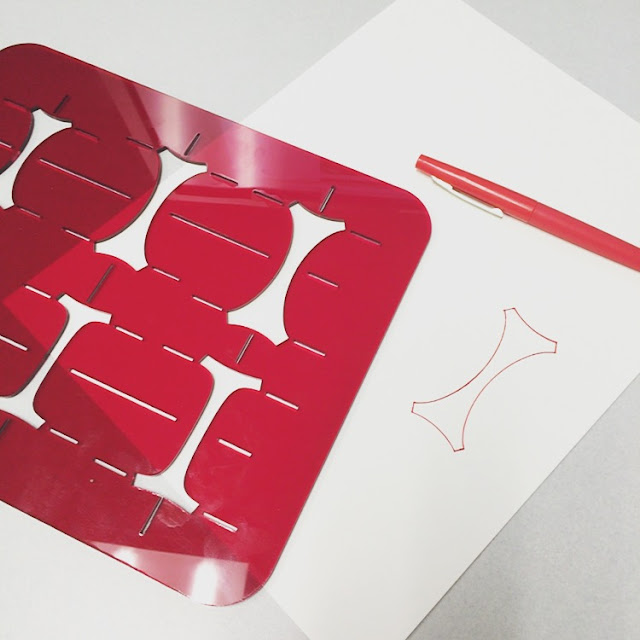

The sophomores are making H-pattern rings which is exciting. We all practiced making patterns in illustrator. Of course I had to take it a step further and make a laser cut stencil to trace the patterns on the metal. I might have to sell these things!

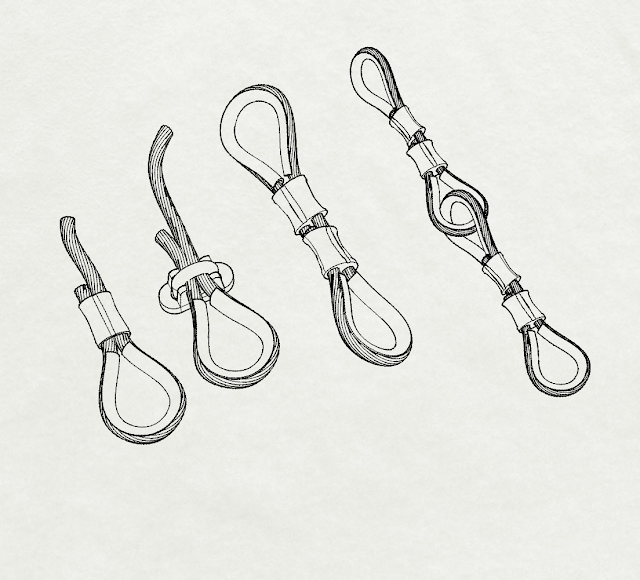

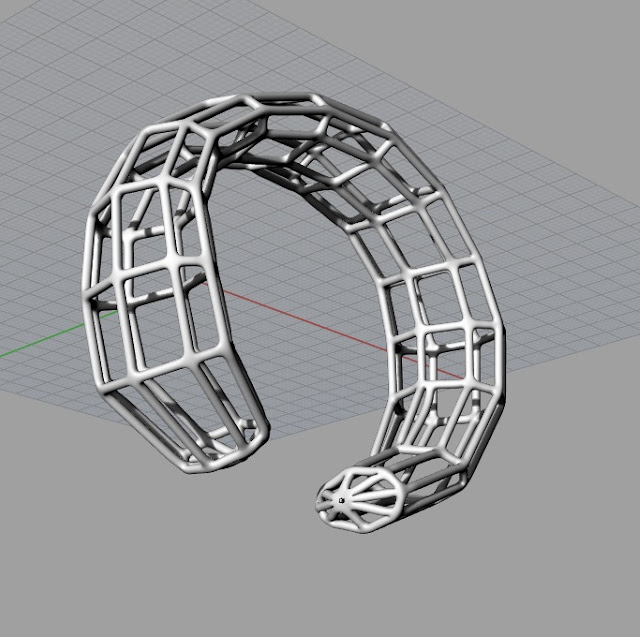

I have a big show coming up in July. I am working on larger 3D printed neckpieces and bracelets loosely based on how self referential contemporary jewelry can be and how torn I am between the bench and the computer (more on that later). I started modeling a cable chain necklace which will be printed in Nylon and have a metal component. For now I am testing the smaller parts in resin using the ASIGAs.

I have to amp things up a bit. On top of the large neckpieces I have to make five enameled brooches for ZOOM. I am also working on a cuff version of my silver bangle (renders below). I have not quite figured out if it should be open or shut on the end.

After spying a book in Boris's studio I ended up ordering it! Modell-Lehrgang Fur Goldschmiede It is a german goldsmithing course workbook. It is not in English but it is full of amazing illustrations and handouts. I started recording some of the more interesting pages.

I think that is enough for now.

Don't forget to follow me on instagram. https://www.instagram.com/arhash/

So many things to do!!!

Posted by

arthur hash

Labels:

3Dprinting,

arthur hash,

ArthurHash,

bracelet,

CAD,

New work,

Rhino,

RISD,

shapeways

0

comments

at

3:41 AM

Subscribe to:

Posts (Atom)

.jpg)