I am starting a new project in my CAD/CAM II class here at RISD. This project has a simple requirement: 3D print a piece that accepts a stone. I decided that I wanted to do the project with them in order to familiarize myself with our new ASIGA printers.

Brian Bergeron, the full time metals tech has been helping me perfect my support locations as well as understanding the little nuances of the printer.

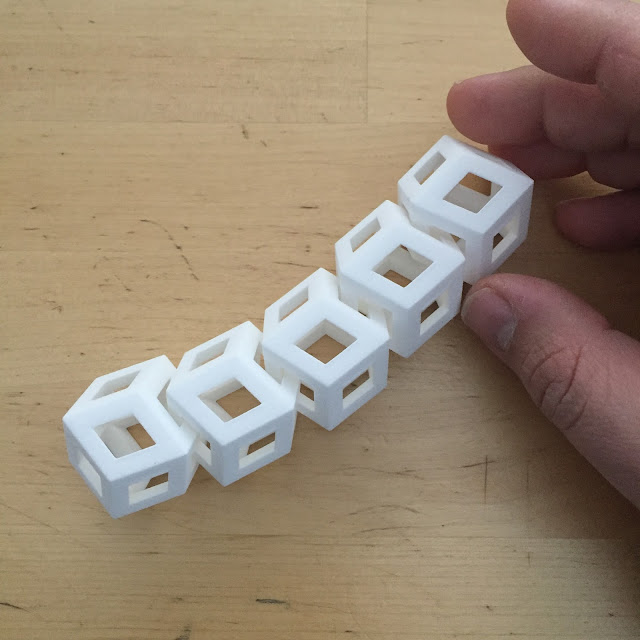

I will have to go into an in-depth review later, when I have time but for now I have a few first impressions. First, the print area is small. It is roughly the size of five matchboxes. You could print six rings or a large brooch. You might be able to squeeze in a bracelet if you split it in half. I have only printing in the lowest resolution which allowed me to print three rings in under an hour and a half. I find that to be quite impressive give the time that it takes the FDM machines to print. At the lowest resolution I can see the print layers with my eye but prints at the highest resolution have no visible marks from the printing process.

I wanted to try a tension setting. I started by ignoring all the rules and just printing a ring that looks good but probably wouldn't work. While that one was printing I started on a second ring. Adding material here and there until I got something that might work. If I try to make it work I will probably end up casting it in 14K yellow or 10K white gold to make sure there is enough tension in the material.

.jpg)