Friday, November 15, 2013

Sunday, November 10, 2013

ex-spare-mints

at

4:08 PM

Friday, November 8, 2013

knife part II

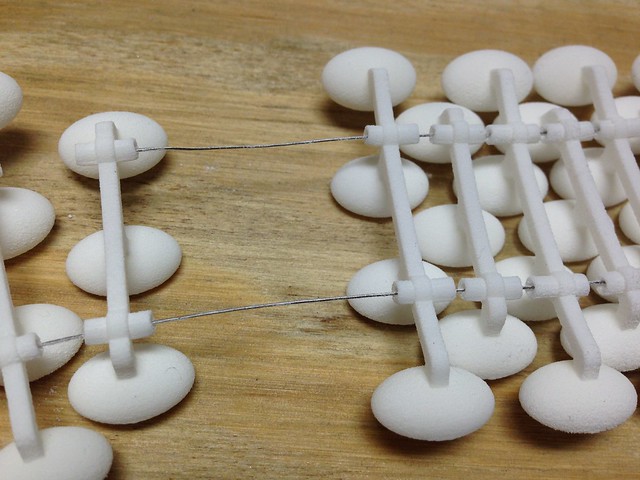

So I picked up the knife blanks.

Here is what I learned:

- I used 1/8"

301304 stainless which may be a little too thick 301304 stainless is not hardened tool steel so I need to experiment with cutting to determine how long the edge will keep. 301 is the same stainless industrial kitchen table tops are made from.- My design is not perfect. I think the handle needs to be longer in order for it to be better balanced and usable.

- I made two sizes, the larger blade is about eight inches long. Unfortunately the handle on the larger knife is WAY too small.

- I need to figure out how to stamp or mark the blade.

- I am also rough grinding the blade as much as I can and then I am actually having the edge ground by a cutlery expert near the CIA (Culinary Institute of America). I would love to do it myself, but until I can get a hold of some proper tools (Belt grinder etc) I am going to leave it to the experts.

- I have to alter the design a bit but I would like to make more soon for the holiday season.

- I should really put a hole in it, either for rivets or for it to hang on something.

at

6:51 AM

Tuesday, November 5, 2013

knife research Part ONE

Sooooooo coming off making two cutting boards for friends I have decided to do a limited run of knives.

On with the research.

Sometime last year I thought it would be great to make a couple of knives. I ordered some knife steel and quickly realized..... that I didn't have the right tools to make what I wanted. I burned up bits, I snapped sanding belts and melted few things. Plan B, fast forward to today. I thought I would laser cut the metal and then all I would have to do it put on an edge and maybe make a handle?

So a little research. First, I found this website that was incredibly informative. This website made me realize that I was missing some of the vocabulary and design elements that would be necessary to even attempt making a a knife.

I have a lot of experience with knives. Ever since I was a teenager I have always had a knife on me or near me. It all started with the swiss army knife then later a folding spyderco, then a gerber, saber on and on and on. When I was older, working on two houses and having a full time job teaching studio classes I was actually detained at an airport because I forgot to leave my knife at home. I also love cooking and using knives in the kitchen. De-boning turkeys, chickens and roasts. Cutting Soba noodles.

I have started designing a few things in Rhino and have based the design on a basic vegetable chopping knife/chefs knife hybrid. I made two sizes thinking that one might make a great bench knife or prep knife.

at

8:42 AM

Wednesday, October 30, 2013

Getting it done

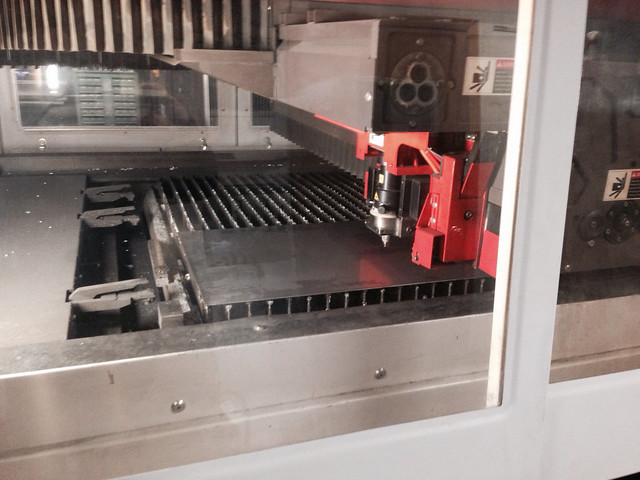

So I had recently been invited to do a craft holiday sale. I thought that I would make some cutting boards and knives. I have been doing some research and found a local company to cut the stainless for the knives after which I will grind and finish them myself. I think this will work a lot better than cutting them from blanks. They gave us a tour of the facility which was kind of eye opening. I have to admit it is very nice to have this in your back yard. I actually had to kind of shut my brain off for a while so I can focus on knives. There are so many things I would like to make with all of this equipment.

Not only do they have a super laser! They also have a CNC turret punch which is used to cut holes, straight lines, knockouts, louvers etc. For some things it is cheaper to mechanically stamp/shear/form than to laser. Also aluminum is far safer to stamp than laser because of fumes etc.

at

6:28 PM

Subscribe to:

Comments (Atom)

.jpg)